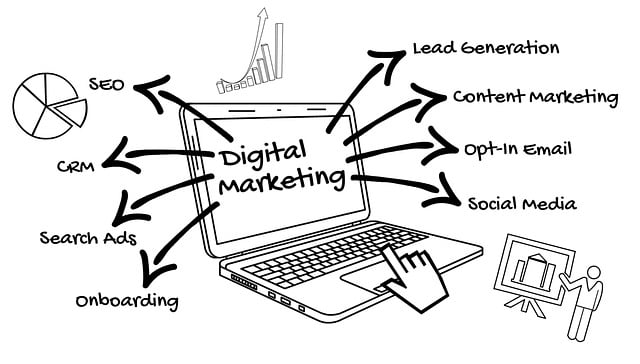

AI productivity tools are revolutionizing automotive shop management by automating tasks, improving efficiency, and reducing costs. Leveraging machine learning, these tools handle inventory, scheduling, and reporting, freeing human resources for complex diagnostics. Through data analysis, AI optimizes inventory management, predicts maintenance needs, enhances task scheduling, and integrates with existing software, resulting in increased profitability and reduced downtime for auto businesses.

“The automotive industry is undergoing a quiet revolution as AI cost-saving strategies transform traditional auto businesses. This article explores three powerful AI productivity tools tailored for automotive shop management. By automating routine tasks, leveraging data-driven insights for inventory and resource allocation, and implementing predictive maintenance, shops can streamline operations, reduce downtime, and optimize costs. Discover how these AI integrations are paving the way for a more efficient and profitable future in automotive service.”

- Automating Routine Tasks: Streamlining Operations for Time and Cost Efficiency

- Data-Driven Decision Making: Optimizing Inventory Management and Resource Allocation

- AI Integration for Predictive Maintenance: Reducing Downtime and Operational Costs

Automating Routine Tasks: Streamlining Operations for Time and Cost Efficiency

In today’s digital era, AI productivity tools for automotive shop management offer a game-changing approach to automating routine tasks and streamlining operations. By leveraging machine learning algorithms, auto businesses can significantly enhance time and cost efficiency across various functions. For instance, AI can automate inventory management, scheduling appointments, and generating reports, thereby freeing up human resources to focus on more complex and value-added activities like diagnostics and repairs.

This automation not only reduces the likelihood of human error but also ensures consistent and optimized processes. As a result, auto shops can better manage their workloads, minimize wasted time, and ultimately reduce operational costs. In a bustling industry where every second counts, AI productivity tools are instrumental in maintaining high levels of service quality while keeping expenses in check.

Data-Driven Decision Making: Optimizing Inventory Management and Resource Allocation

In today’s digital era, embracing AI productivity tools for automotive shop management can significantly transform how businesses operate. Data-driven decision making is a powerful strategy that leverages AI to analyze vast amounts of data and provide actionable insights. By implementing advanced analytics, auto shops can optimize their inventory management processes, ensuring they stock the right parts at the right time, reducing overstocking or understocking risks.

This approach also extends to efficient resource allocation, where AI algorithms can predict maintenance needs, schedule tasks more effectively, and streamline workforce planning. As a result, automotive businesses can minimize labor costs, enhance operational efficiency, and ultimately improve overall profitability.

AI Integration for Predictive Maintenance: Reducing Downtime and Operational Costs

AI integration for predictive maintenance is transforming auto businesses by significantly reducing downtime and operational costs. These advanced AI productivity tools leverage machine learning algorithms to analyze vast amounts of vehicle data, identifying patterns that indicate potential maintenance issues before they occur. By anticipating equipment failures, auto shops can schedule repairs more efficiently, minimizing unplanned shutdowns and their associated costs.

This proactive approach allows automotive shop managers to optimize resource allocation, reduce labor costs, and enhance overall operational efficiency. AI-driven predictive maintenance systems can also integrate with existing shop management software, providing a holistic view of vehicle health, parts inventory, and technician availability. This integration streamlines workflows, further boosting productivity and bottom line savings.

Implementing AI cost-saving strategies, such as automating routine tasks, leveraging data-driven decision making, and integrating AI for predictive maintenance, can significantly enhance the operational efficiency of auto businesses. By embracing these AI productivity tools for automotive shop management, businesses can reduce downtime, optimize resource allocation, and ultimately lower costs without compromising quality. These advancements not only benefit the bottom line but also enable auto shops to stay competitive in a rapidly evolving industry.